Careful and thorough maintenance can keep agv in good working condition. To ensure the safety of the forklift, that is, to ensure the safety of your work and life.

Problem check

- Leakage inspection: hydraulic oil, electrolyte, brake fluid

Check the hydraulic pipe joints, lithium battery, and brake system for oil or fluid leakage, touch them with your hands and inspect them visually. The use of open flames is strictly prohibited.

- Check shelf and fork

Check whether the racks, forks are cracked, twisted, and the bolts are fastened, and check whether the fork positioning pins are locked.

- Inspection of front and rear wheels

Check whether the front wheels and rear wheels are cracked, damaged, or abnormally worn, whether there are entangled wires; whether the tire nuts are loose, and whether the tire bearings are damaged.

- Electromagnetic brake inspection

Check whether the electromagnetic brake is working properly.

- Hydraulic oil inspection

When checking the fuel tank, first unscrew the filler cap, pull out the dipstick, and check the oil level. The engraved numbers on the oil dipstick represent the height of hydraulic oil required for various mast heights. If the actual hydraulic oil level is lower than the height required by the corresponding mast, please add hydraulic oil.

- Lithium battery inspection

Check whether the lock pin is firmly installed, that is, whether the battery box is firmly and reliably fixed. Check the connectors of each line of the lithium battery.

- Safety function check

Regularly remove dust from the safety laser; check the photoelectricity of the fork tip, the fork tip anti-collision mechanism, and the contact edge

- Check the operation interface of the instrument case and the red emergency stop button

Check whether the operation interface of the meter, all switches, meters, etc. work normally; whether the red emergency stop button of AGV works normally.

- Check the tension of the mast chain

The fork is raised by 10cm~15cm, and the mast is vertical. Press the middle of the chain with your thumb to check whether the tension of the left and right chains is the same.

- Horn

Press the horn button to check the sound of the horn.

- Check AGV vehicle control check

Check whether the AGV vehicle is reliably controlled, and simulate whether the AGV route trajectory and spatial positioning are accurate.

- Other – Such as abnormal noise inspection.

Note: In addition to inspecting lamps and checking operational performance, before inspecting the electrical system, the key switch must be turned off and the lithium battery plug must be unplugged. It is forbidden to use AGV with any malfunction.

Maintenance Notes

- Regularly clean the dust and debris of the AGV body to keep it clean and hygienic.

- Pay attention to regular inspection of the AGV operation panel, keep the operation panel clean and dry, free of clean, dust, oil, etc. Ensure that the buttons on the panel can be used normally.

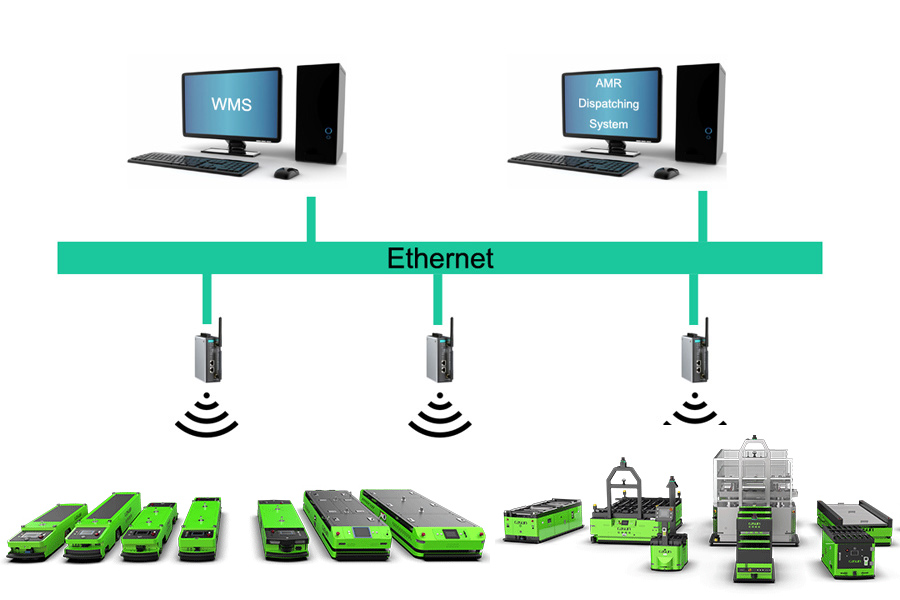

- Check the antenna communication regularly to keep the communication normal.

- Regularly check whether the sensors on the car are working properly. It is recommended to check at least once a week.

- When using the AGV logistics system, be sure to start the central control system first.

- It is strictly forbidden to get in the rain or touch corrosive objects.

- Turn off the power during holidays. If the lithium battery is stored for a long time, please fully charge it at least once a month, and ensure that the battery power is not less than 90% when the AGV is idle.

- It is strictly forbidden to modify the program parameters during normal operation.

- Regularly clean the transmission mechanism of the driving wheel and add lubricating oil. It is recommended that it be at least once a month.

- Clean and add lubricating oil to the lifting hook regularly, it is recommended 1-2 times a week.