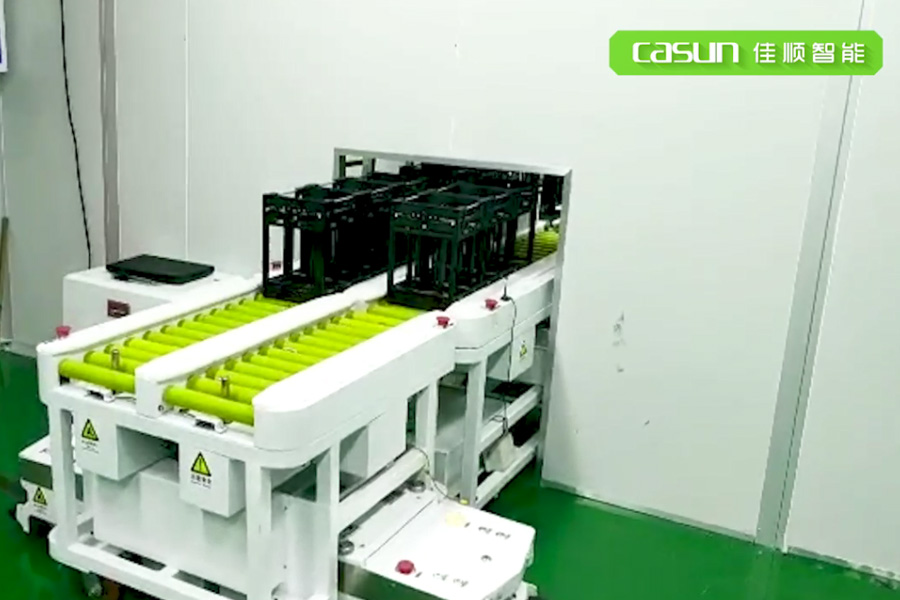

lithium battery PACK manufacturing line intelligent upgrade application sharing

Introduction of new energy lithium battery pack line New energy lithium battery PACK generally refers to packaging, packaging, and assembly. For example, 2 batteries are connected in series to form a specific shape according to customer requirements, which is called PACK. As a key step in the production, design, and application of new energy lithium-ion […]

lithium battery PACK manufacturing line intelligent upgrade application sharing Read More »