The cushioning materials consumed during the storage process account for a large proportion of the storage cost. Therefore, the greatest potential for reducing storage costs lies in saving cushions and covering materials and related labor costs, looking for material management methods that can save this part of the cost and ensuring the quality of material management, and carrying out technological innovation and technology. Transformation to fully tap the potential of the equipment. At the same time, separate and classified management should be implemented in the management of storage costs, and economic accounting should be strengthened to promote the continuous reduction of storage costs.

Contents

Management of loading and unloading costs in warehouses

Materials entering and leaving the warehouse mainly rely on loading, unloading, and handling operations to complete. The equipment depreciation cost of loading and unloading handling machinery is the largest proportion of the cost of handling and handling in the warehouse. Therefore, the storage department should first pay attention to the economy and practicability when selecting suitable machinery and equipment. We should prevent the practice of unreasonably increasing the depreciation of storage equipment in disregard of actual needs and greed for foreigners.

Management of warehousing labor costs

There are two main aspects to the expenditure of warehousing labor costs: one is the wages, bonuses, welfare fees, and allowances of warehouse management personnel; the other is the wages, bonuses, allowances, and welfare fees of warehouse production workers. The management of warehousing labor costs should focus on minimizing the wages of non-production workers because this part of the cost has no direct relationship with the volume of warehousing operations. At the same time, labor productivity should be continuously improved, and the consumption cost of living labor in storage costs should be continuously reduced. In addition, choosing a reasonable form of labor organization and wages also has an important impact on reducing labor costs.

Management of other warehousing costs

In the storage costs, such as oil, fuel, electricity, low-value consumables, and other costs, although a small proportion, the management of this part of the cost can not be ignored. Warehousing cost management should focus on continuously reducing the level of the above-mentioned cost items.

Measures for warehousing cost control

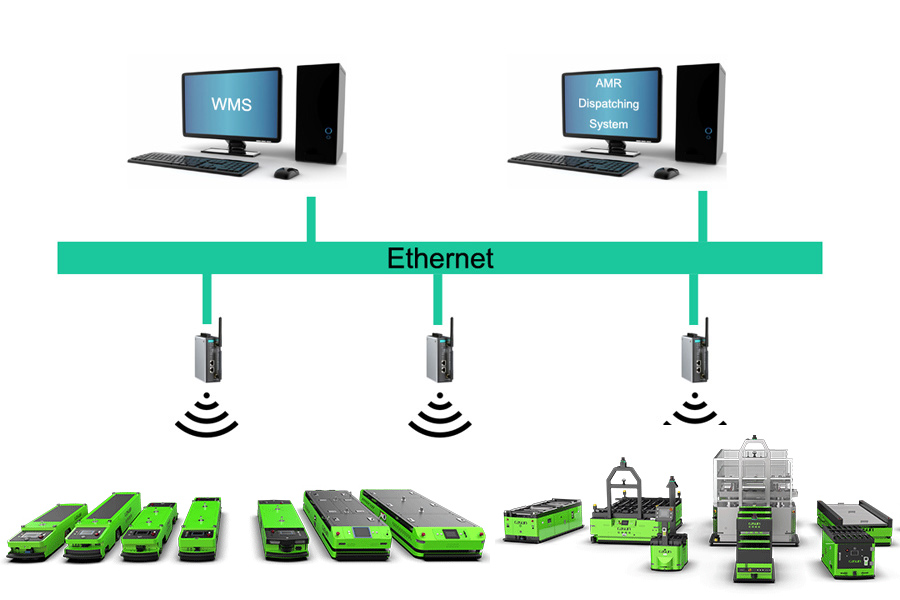

- 1 Make full use of modern storage technology and equipment to improve the efficiency of each work link. In a warehouse, a certain amount of work expenses, due to the actual work efficiency is different, the labor, mechanical equipment consumption, and fuel costs are different. If the warehouse management is performed well, the entire storage cost will be reduced, which is economical. Benefits will increase. Therefore, modern warehousing technology and equipment should be used in warehousing operations to improve labor productivity, such as the use of computer positioning systems, computer access systems, computer monitoring systems and other computer management technologies, warehousing barcode technology, modern shelves, professional operating equipment, forklifts, New pallets, etc.

- 2 Accelerate the turnover of raw materials and finished products of the enterprise, give full play to the efficiency of warehouse yards, and increase the utilization rate of warehouse capacity. Accelerated inventory turnover speed can make enterprises’ capital circulation faster, capital appreciation faster, cargo damage and cargo difference small, warehouse throughput capacity enhanced, and costs reduced. Giving full play to the efficiency of warehouse yards is a prerequisite for reducing storage costs.The warehouse department can adopt the method of high stacking to increase the storage height; reduce the width of the channel in the warehouse to increase the effective storage area; use side forklifts and push-pull forklifts to reduce the width required for forklifts to turn; reduce the number of channels in the warehouse to increase storage Effective area. The ton/day cost of warehousing goods is closely related to the utilization rate of the warehouse area and the amount of goods stored.

- 3 Strengthen the quality management of materials and finished products in the warehouse to reduce abnormal losses during storage. The quality of the goods stored in the warehouse is intact and the quantity is accurate, which reflects the quality of warehouse management to a certain extent. In order to avoid or reduce the loss of goods, we should strictly inspect the goods in the warehouse, so that unqualified materials and finished products will not be put into the warehouse, and the materials will never be issued when the procedures are incomplete, and the products with quality problems will never be shipped. The raw materials and finished products are classified and stored in divisions, stacking is carried out scientifically, the temperature and humidity of the warehouse are controlled, and the items in the warehouse are checked regularly to ensure that the bills are consistent, the accounts are consistent, and the accounts are consistent. A slight error in the actual work will cause the accounts to be inconsistent. Therefore, the actual storage situation must be grasped in time and accurately, and the account card must be checked frequently, whether it is computer management or manual management, which is indispensable.

- 4 The effective “first in first out” method is adopted to ensure that the storage period of each stored item is not too long. It is an effective method and has become one of the criteria of storage management. The effective “first in, first out” methods mainly include: First, the use of management software. According to the time when the items are put into the warehouse, relying on chronological sorting, the order of shipment can be automatically arranged, so as to realize “first in, first out”. The management software can also combine first-in, first-out and fast-forward and fast-out to speed up turnover and reduce labor consumption; the second is to adopt a technical process system method in the warehouse to ensure “first-in, first-out”. The most effective method is to adopt the through-type racking system in the technical process of the warehouse, which can not only improve the utilization rate of the warehouse, but also realize the mechanization and automation of the warehouse management, which is an important technical measure of the modern warehouse.

- 5 Strive to keep the logistics, information flow, and capital flow consistent to enhance the effectiveness of management. Make full use of the advantages of informatization, networking, and intelligence of warehouse management under e-commerce to effectively control the import, sale and storage systems to keep the logistics, capital flow and information flow consistent. The use of dynamic data of logistics, capital flow, and information flow to assist decision-making can effectively reduce the cost of inventory and improve the efficiency of warehousing services.